Product Information

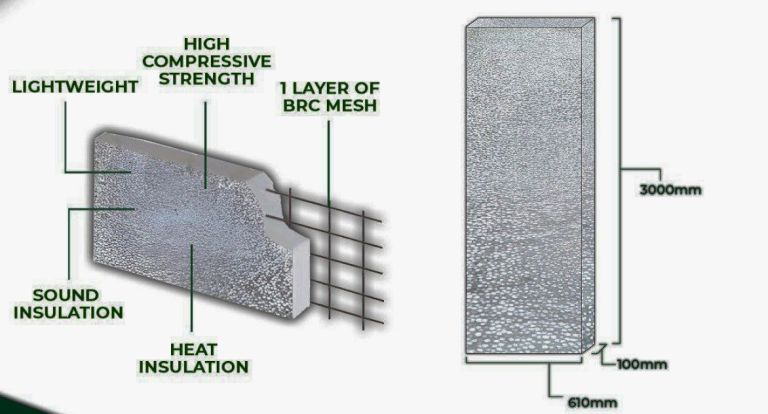

V-PLUS Panel

The V-Plus Panel is an innovative construction solution designed for quick and efficient wall installation, providing strength, durability, and adaptability for various structural needs. Ideal for both residential and commercial applications, the V-Plus Panel simplifies installation while maintaining high-quality standards.

V-PLUS Panel

The V-Plus Panel is an innovative construction solution designed for quick and efficient wall installation, providing strength, durability, and adaptability for various structural needs. Ideal for both residential and commercial applications, the V-Plus Panel simplifies installation while maintaining high-quality standards.

Materials & Tools

V-Plus Panel

Cement Adhesive

Skimcoat Adhesive/ Plaster Render

Cement Blender

Circular Saw

Scrapper

Cement Scope

Grinder

Drill

Water Level

Y10 Steel

Ladder

Concrete Nail

Fiber Mesh

Timber

Staging

R6 Steel

Installation Process of

V-Plus Panel

1. Site Preparation

i) The column/beam/common brick/shear wall should be accurately aligned, with good surface in order for V-Plus Panel to be joined properly.

ii) Floors must be levelled and site cleaned from debris before set out marking line.

2. Setting Out

i) Set the marking line for V-Plus Panel placement using ‘maktau’ ink method.

ii) Mix the cement adhesive with 4:1.25 ratio to the water using blender.

iii) Apply cement adhesive on the floor following the marking area before installing every V-Plus Panel.

3. Arrangement of V-Plus Panel

Place the V-Plus Panel neatly according to the marking.

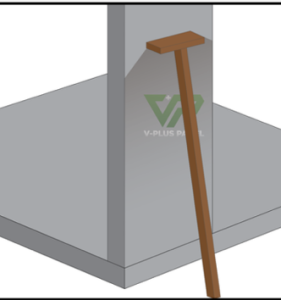

4. Installation of Timber Formwork

Hold the V-Plus Panel using timber formwork perpendicular to the floor level.

5. Applying Cement Adhesive

i) Mix the cement adhesive with 4:1.25 ratio to the water using blender.

ii) Paste the cement adhesive on the side of V-Plus Panel.

6. Installation of V-Plus Panel

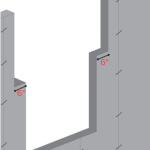

a) Installation of V-Plus Panel (Panel to Panel)

Install the V-Plus Panel to other panel at the corner for starting point.

b) Installation of V-Plus Panel (Panel to Column)

i) Install the V-Plus Panel at the column.

ii) Apply fiber mesh at the joint between panel and column.

7. Locking V-Plus Panel at The Corner

a) Locking V-Plus Panel at The Corner (Panel to Panel)

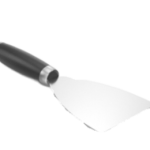

Lock the panel at the corner using 10 inch Y10 steel (minimum 5 locking).

b) Locking V-Plus Panel at The Corner (Panel to Column)

Lock the panel using Y10 steel starter bar at the column (minimum 2 locking).

8. Locking the V-Plus Panels at Top

Lock every panel at the top using 10 inch Y10 steel.

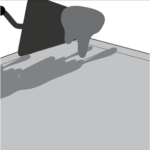

9. Drilling For Bottom Locking

Drill the hole for locking at the bottom.

10. Bottom Locking

Lock the bottom of every panels using ‘7 shaped’ Y10 Steel.

11. Locking The Jointing Between Panel

Lock the jointing of every panels using stapler shaped R6 Steel (minimum 7 locking, 4 pieces inside and 3 pieces outside or otherwise).

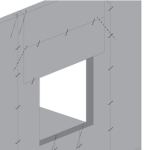

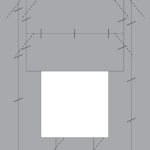

12. Installation of Lintel Beam

i) Cut the panel according to the opening schedule in drawing plan. Make sure the gap for lintel base is 6 inch.

ii) Use the panel to make lintel beam at window and door opening. Apply cement adhesive on each side and place the lintel.

iii) Lock the panel following the step above after the lintel have been placed.

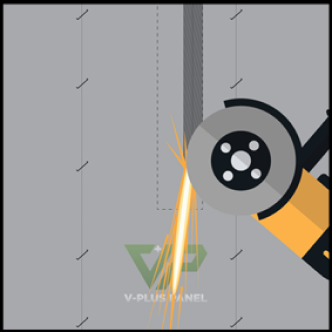

13. Electrical Conduit Installation

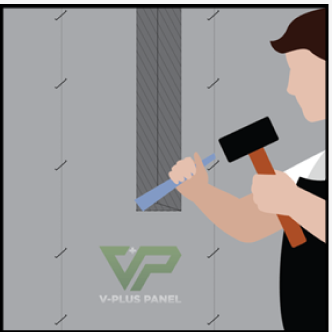

i) Mark the spot that need to be cut.

ii) Cut the marked area using grinder.

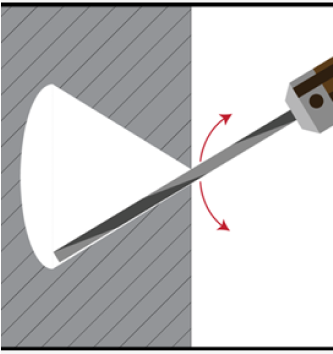

iii) Use the chisel to clean the debris.

iv) Install the electrical pipe in the wall.

v) Fill the void area using mortar.

14. Installation of Lintel Beam

i) Mark the spot that need to be cut.

ii) Cut the marked area using grinder.

iii) Use the chisel to clean the debris.

iv) Install the pipe in the wall.

v) Fill the void area using mortar.

15. Skim Panel Wall / Render Plaster

Skim all the panel wall using Fassa X-Ter.

16. Paint Panel Wall

Paint the panel wall neatly.

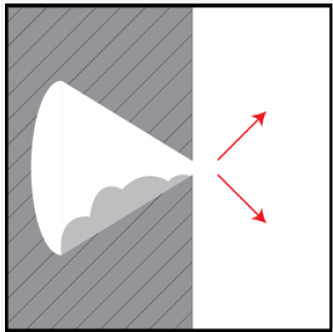

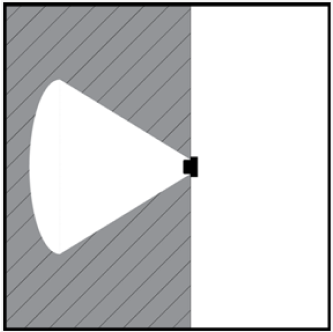

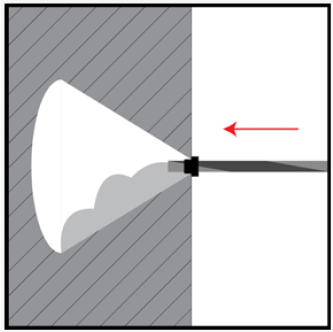

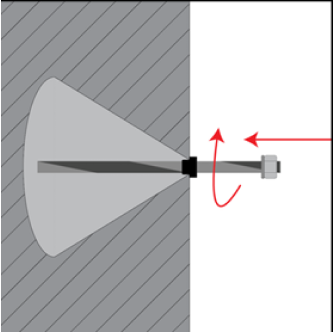

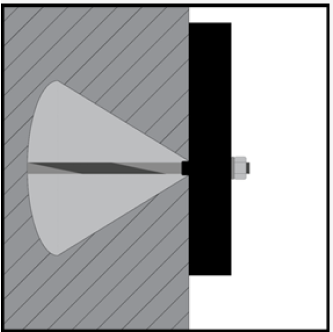

17. Heavy Items Holder Installation

i) Drill Hole

ii) Remove Dust

iii) Insert Sleeve

iv) Inject Chemical Sealant (V-Tech VT-230 / Statheros EPC80 Epoxy)

v) Insert Bolt

vi) Fix Bracket / Nut